Unknown Facts About Sheroz Earthworks

Table of ContentsSee This Report about Sheroz EarthworksIndicators on Sheroz Earthworks You Should KnowFascination About Sheroz EarthworksThe Best Guide To Sheroz EarthworksSome Known Factual Statements About Sheroz Earthworks

For any earthwork service provider, it is essential to carry out collaborate with high quality, precision, and on schedule. Making use of maker control in work machines makes it possible for enhancing the different phases in the earthwork procedure, from intending to the upkeep phase - fj dynamics auto steering kit price. The equipment control system assists the machine operator in acquiring the target aircraft quickly and quickly

The machine control system guides the driver with centimeter accuracy. Remote support saves time and cash, as it decreases downtime in jobsites.

9 Simple Techniques For Sheroz Earthworks

Additional training and instructions are always offered over remote support when needed. The earthmoving industry has actually used our field-proven services given that the early 1990s. Our system's components are very carefully created to endure the harsh conditions of building websites. Comparison of the exact same project performed making use of device control versus the traditional technique reveals that, generally, the standard method calls for 50% more time to complete the same job as the technology-assisted method. https://hubpages.com/@sherozau.

Go into the Xsite maker control system; it's below to give you with a substantial advantage when functioning with earthmoving machinery. Discover exactly how Xsite Maker Control can enhance your performance and ensure job safety! Xsite Device Control systems can be mounted to any excavator from mini excavators to large mining excavators.

Just how does device control job? In 2D systems, the equipment is equipped with calibrated inclination sensors. These sensing units are installed on the pre-determined parts of the device in excavators the sensing unit are generally installed to the framework, boom (or booms), digger arm and to the quick coupler - trimble tripod parts. By utilizing the data received from these sensors the system can determine the precise placement of the excavators bucket tip in relevance to a recommendation point.

The system is very easy to discover the fundamentals can be instructed in under one hour of training. Exactly how does the remote assistance work? A wireless web connection makes it feasible to establish a remote link between the machine control system and the solution.

The Ultimate Guide To Sheroz Earthworks

Xsite Device Control systems sustain open typical data formats, enabling smooth information circulation from one system to an additional. Depending on your choice of system (with or without positioning, i.e., 2D or 3D), your maker is outfitted with inclination sensing units, a controller system, and a display/operating panel.

Numerous hardware and software program remedies exist to assist identify a device's existing setting on the earth and contrast it with a desired layout surfaceand building and construction operators can do more to leverage the advantages. Equipment control is the use of various placing sensors and a display to provide the driver with a recommendation between the placement of the pail or blade and the target quality.

Depending on the configuration, equipment control systems can supply the operator with a simple aesthetic overview to container or blade position, or can instantly relocate the blade to quality by talking with the device's hydraulics - https://www.folkd.com/profile/218747-sherozau/. There are equipment control systems offered for practically any type of equipment: graders, dozers, excavators, dirt and asphalt compactors, scrapers, trimmers, crushing machines, and pavers

The Basic Principles Of Sheroz Earthworks

Device control can additionally assist enhance productivity and minimize overall costs. Building and construction equipment without equipment control will end up being a point of the past and the benefits gained from it will certainly be various.

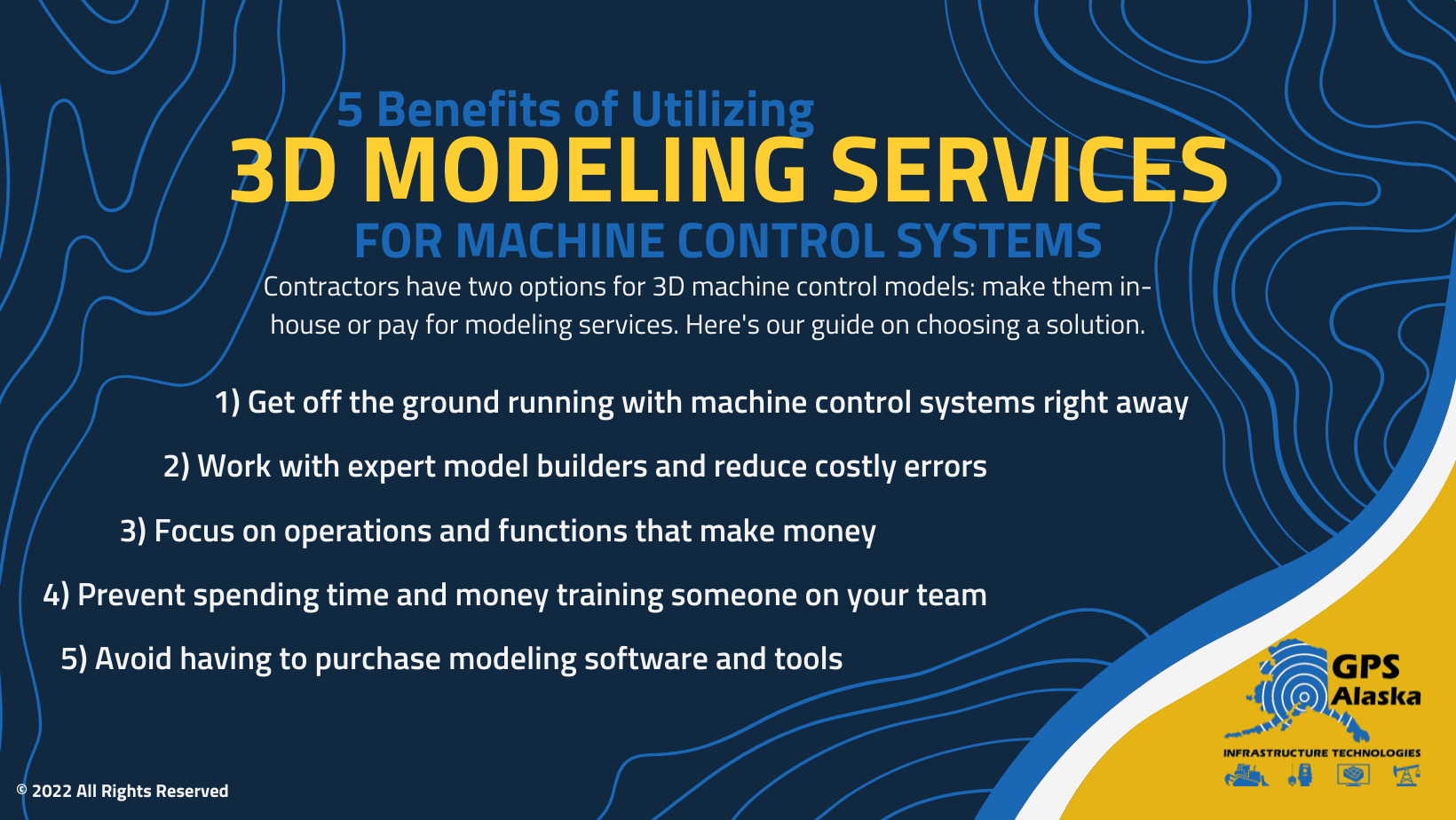

Trimble machine control systems supply a myriad of benefits to any person who uses earthwork machinery and, at EarthCalc, we can provide you with 3D declare your device control-enable equipment. Not certain if equipment control is worth the cost? Consider the complying with reasons you need to consider this alternative.

Utilizing GPS lined up with your 3D design files, these systems virtually assure that you will remove or place the correct amount of material at the building website. On many construction websites, rework is a typical and irritating truth, yet with Trimble machine control, you can remove the need for rework.

See This Report on Sheroz Earthworks

Typically, with Trimble machine control, you can eliminate excess equipment at a specific job site. As an example, a task that could have called for using 3 or four pieces of excavating tools currently may need only 2 items of devices to complete the very same job in much less time. This permits you to relocate your equipment to another work site and handle multiple browse around this web-site jobs at one time.